Each year, innovations in hemp plastic technology hit the market and many companies are incorporating hemp plastics into their products. Hemp is proving to be a clean alternative to the highly polluting plastics that are damaging our environment. There are various types of hemp plastic; here, we will briefly take you through how these plastics are produced.

Why is there a need for an alternative to plastics?

There is no doubt that we are experiencing a major environmental crisis that takes many forms. Human beings have followed a non-sustainable development model for which we are now suffering the consequences. The already perceptible change in climate, the significant loss of biodiversity and, of course, the pollution of the soil, the air and the seas are some examples of the damage we have caused to our environment.

Take our seas and oceans, for example, which we have turned into a gigantic repository of rubbish that threatens marine ecosystems. According to Greenpeace, every second more than 200 kilos of plastic are dumped into the world’s oceans and seas, which is equivalent to more than 8 million tonnes of plastic waste a year.

In addition, more than 1 million seabirds and over 100,000 marine mammals die annually because of the damage caused by plastic, chemical and oil waste to the marine environment. Although some of these residues, which accounts for 80% of all sea pollution, can degrade and disappear in just over six months, many others take several hundred years to do so.

Meanwhile, plastic waste, including “microplastics”, leaves a great deal of air, sea and land pollution. A team of scientists recently demonstrated that these microplastics are dispersed through the air and reach remote natural areas, with concentration levels similar to those found in large cities.

International governments and environmental organizations have already begun to act to stop this serious global ecological threat. However, the targets set in the various international agreements for 2030 and 2050 seem somewhat unattainable for many countries and regions.

We need urgent measures to stop plastic pollution, and each of us must try to do our part to innovate, change mentalities and respect the environment. Our lives and future depend on it.

Hemp: A raw material returns from the past

Hemp is the plant that has the potential to help us reinvent the future of plastic and other materials. It is a clean, ecological, sustainable and renewable alternative. And it can replace the use of polluting materials in the production of goods in many fields, such as construction, automobiles, fashion, design, sports, and many others.

But hemp is not a new resource that responds to a specific ecological trend. Hemp is a raw material that returns from the past to help us rethink the future. For millennia, it has been used for its nutritional properties and multiple health benefits, and it has served as a raw material for countless products such as food, textiles, and medicines.

Hemp is among the crops that creates more biodiversity in its surroundings. Its cultivation allows us to obtain at low cost three raw materials: the seeds, the fibre and the pulp. Fibre has always been the most used for its excellent qualities, as it is the most resistant, absorbent and durable fibre of vegetable origin.

Reinventing the future of hemp plastics

It is becoming increasingly easy to find products aimed at various sectors made from vegetable fibres, such as flax, coconut and, of course, hemp. The aim is to replace the polluting materials that have been produced for decades. As we have said, hemp can replace many of these materials, such as plastics, thus helping reduce pollution worldwide.

The use of hemp not only entails an ecological benefit. It also improves the quality and performance of the products containing it. For instance, hemp fibre has long been used, instead of fibreglass, to make surfboards as it makes them much lighter, more flexible and resistant, and gives them sensational grip and buoyancy.

Thus, with increasing frequency each year, innovations in hemp plastic technology come onto the market. Today, even some of the largest automobile companies such as BMW, Mercedes and Bugatti incorporate hemp plastics in their products. The latest Porsche model, for instance, the 718 Cayman GT4, incorporates hemp fibre panels manufactured by the Dutch company Hempflax.

In short, bioplastic materials, including hemp, offer significant advantages for the environment. Because they are not made from fossil fuels, they do not produce carbon dioxide when decomposed. In addition, most of them are biodegradable. Everything indicates that they could be a very important part of solving the climate crisis.

5 types of hemp bioplastics and how they are used

1. Hemp cellulose

Cellulose is the most abundant organic polymer on Earth, and is an integral part of the cell walls of plants and many algae species. Although cellulose is mainly used to make paper, it is also used to make a wide range of different plastics, including celluloid, cellophane and rayon.

The first plastics were made from organic and non-synthetic materials, and cellulose was then a key element in the nascent plastics industry. Today, bioplastics have again attracted great interest for their diverse environmental benefits.

2. Cellophane, rayon and celluloid

Both cellophane and rayon are classified as regenerated cellulose fibres, and are similarly produced to make cellophane film or rayon fibre.

Celluloid is obtained by producing nitrocellulose (cellulose nitrate) first, which is mixed with camphor, a widely used plasticizer, to yield a dense, solid thermoplastic that can be easily moulded when heated.

Hemp cellulose can be extracted and used to make cellophane, rayon, celluloid and a variety of related plastics. Hemp is known to contain around 65-70% cellulose, and is considered a good promising source, largely due to its relative sustainability and low environmental impact. By comparison, wood contains around 40% cellulose, flax 65-75% and cotton up to 90%.

Hemp grows faster than most tree species, and requires fewer pesticides than cotton or flax. However, a significant amount of fertilizer is required when grown in some soils, and it also needs a relatively large amount of water.

3. Other products made from hemp cellulose

Cellulose can be used to manufacture a wide range of plastics and related substances. The difference in physical properties is largely due to the length of the polymer chains and the degree of crystallization.

Cellulose is extracted from hemp and other fibre crops using different methods. The raw pulp can be hydrolysed, i.e. separated into its component parts by adding water at 50-90° C. It can also be immersed in a weak acid solution to separate the crystalline sections from the amorphous ones, thereby producing cellulose nanocrystals.

Extra heat and pressure can also be applied to it to produce an interesting form known as nanocellulose. This is a “pseudo plastic” that resembles a viscous gel under normal conditions, and becomes more liquid when agitated or stressed.

Nanocellulose or microfibrillated cellulose (MFC) has a wide variety of potential applications. It can be used as a reinforcing material in plastic compounds and as a highly absorbent agent to clean up oil spills or oil slicks. It can also be used to manufacture sanitary products, and as a low-calorie stabilizer in food technology.

Zeoform, an Australian company, offers a cellulose-based plastic material manufactured using its own patented process, which includes hemp.

Through their technique, cellulose fibres are converted into a mouldable material that has a high industrial strength for an unlimited variety of products. This material is advertised as 100% non-toxic, biodegradable and recyclable as it can be composted and offers a very interesting form of carbon capture and sequestration.

4. Hemp-based plastics

Composite plastics consist of a polymer matrix, which may be based on cellulose or a range of other natural or synthetic polymers, and reinforcement fibres, which in turn may be of natural (and mainly composed of cellulose) or synthetic origin.

Natural polymers include tar, shellac, tortoiseshell, and many tree resins, while natural fibres include jute, sisal, cotton, and flax. Traditional inorganic fillers include talc, mica and fiberglass.

Biocomposites generally have at least one major component of organic origin. Although 100% organic plastics exist, most contain some synthetic elements. Typically, a natural fibre is blended with a synthetic polymer and then labelled as biocomposite. The various combinations of natural fibres and polymers that can be used to make bioplastics vary greatly in density, tensile strength, stiffness, and other aspects.

These factors can be modified during the manufacturing process to create suitable products for a wide range of applications. The latter include the fabrication of building materials, furniture, musical instruments, boats, car panels, biodegradable shopping bags, and in medicine, biocompatible “supporting structures” in bone tissue reconstruction.

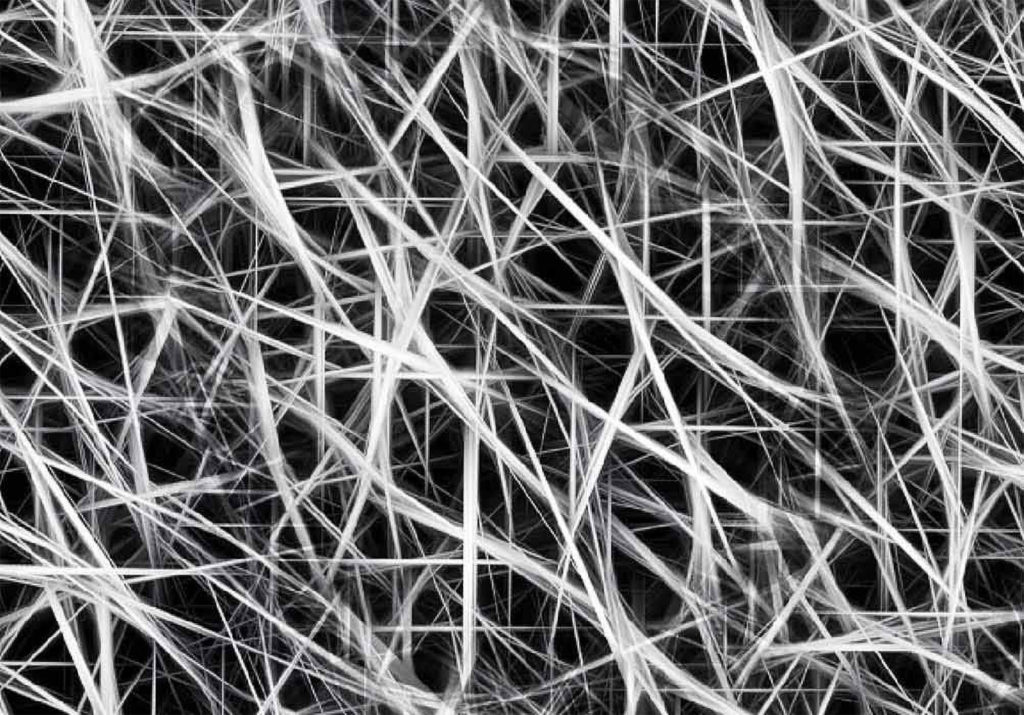

Hemp fibres are used as reinforcement in composite materials and are known for their tensile strength, in particular female plant fibres. Male plant fibres are finer, softer, and often more durable, but they are also less resistant.

A 2003 study of natural fibre-reinforced polypropylene (PP) composite materials showed that hemp, kenaf and sisal had a tensile strength comparable to that of traditional fibreglass composites, and that hemp outperformed its competitors in impact resistance.

In 2007, another study on PP composites reinforced with hemp fibres, in this case by using a material known as malleated polypropylene (MAPP), showed that overall stress and mechanical properties were increased by up to 80% compared to traditional glass fibre composites.

5. Pure biocomposite materials made from hemp

Several biocomposites or biomaterials have already been developed entirely from organic substances, including hemp which is used as a filling material.

In a study conducted in 2003 on the tensile strength of hemp fibres, it was shown that when alkalized with dilute sodium hydroxide (NaOH) in concentrations of 4-6 %, they exhibit greater tensile strength and stiffness when combined with the liquid polymer matrix of the cashew shell in the manufacturing of biocomposite plastics.

A group of Korean researchers announced in 2007 the creation of a biocomposite produced from organic polylactic acid (PLA, an important biodegradable thermoplastic polyester) reinforced with hemp fibres. They also discovered that treating hemp fibres with diluted alkali increased their tensile strength. Biocomposite materials showed higher strength and stiffness than plastics containing only PLA.

In 2009, a group of researchers from Stanford University announced the development of a hemp fibre reinforced composite made from biopolyhydroxybutyrate (BHP). Materials made of hemp and BHP are strong, soft, attractive and durable enough to be used in construction, furniture and flooring materials.

In a 2014 study on the development of fully biodegradable composite materials using poly (butylene succinate) (PBSu) as a polymeric matrix and hemp fibres and hemp shives as a filler, it was found that tensile and impact strength are both affected by the type and amount of filler used. PBSu/Hempagramice compounds had higher biodegradation rates than PBSu/Hemp fibre compounds.

Towards a sustainable future

Clearly, research still has a long way to go before the best sustainable alternatives to petroleum-derived plastics are achieved. However, new research is accelerating as governments and nations around the world become more aware of the need to drastically reduce the use of petrochemicals. And hemp is increasingly being recognized as having tremendous potential in our natural ‘toolbox’ of promising crops for bioplastics.

Hello,

I find hemp a very interesting culture and I have land in Bulgaria. For a while now I am thinking of growing hemp but I do not know where can I sell my production and will it be profitable. Can you please guide me where I can find answers to these questions?

Kind regards,

Kostadin

Good morning Kostadin,

Thanks for your question.

Unfortunately, Industrial hemp is not our area of expertise.

For this kind of enquiry, we recommend you contact the European Industrial Hemp Association.

Thanks again, and I hope you continue to enjoy the blog.

Have a great day!

Mark

Hi Kostadin,

A few years ago I was interested in growing industrial hemp in Bulgaria, but I was unpleasantly surprised to find out that after harvesting the hemp, the seeds are the only part of it that you can take. Everything else must be burned. According to Bulgarian legislation, you need a permission to grow industrial hemp, which you will receive after a registration procedure, which is not such a problem.

In Iowa, the farmer that I talked to about raising Hemp as an alternate crop, shrugged it off. The reason he gave was the high cost of freight from the field to the Hemp processing plant. I wonder if there is an economical way to process Hemp in steps, reducing the freight cost down to a profitable level. This would allow more processing plants to partially process Hemp and ship the components to larger factories which would solve the freight expense. Just thinking.

Good afternoon Marvin,

Thanks for getting in contact with us, and sharing your thoughts on industrial hemp production.

I would definitely like to see more hemp being grown across the United States. Here in Northern Europe our sister company HEMPFLAX produces hemp in The Netherlands, Germany and Romania.

I would recommend contacting the National Hemp Association to see if they can help you further.

These articles on Can Cannabis Reduce CO2 & Help Reverse Climate Change? and The HempFlax Company Story: European Leaders in Hemp Solutionsmight also be of interest to you.

I hope you continue to enjoy the blog.

With best wishes,

Mark

You could definitely see your enthusiasm in the work you write. The world hopes for more passionate writers such as you who are not afraid to say how they believe. All the time go after your heart.

Good morning,

Thank you for your comment!

I’m pleased you enjoyed the article on Hemp Plastic.

You might also enjoy our piece on The HempFlax Company Story: European Leaders in Hemp Solutions.

Thanks again. Enjoy the blog.

Mark

I own Imperial CBD extraction and we get an organic polymer as a byproduct from our extraction method. I’ve got a surplus of inventory of this and I’m looking for a partner to work with. It comes out thru the distillation stage. Liquid polymer but hardens to a solid with hours.

Good afternoon John!

Thanks for the comment and sharing your experience with hemp as an organic polymer, the process sounds very interesting.

This article on Hemp Fabrics 101 & How Hemp Textiles Are Made might also be of interest to you.

Best of luck finding a partner, and I hope you continue to enjoy the blog!

Have a great day,

Mark

yo i used to own a rec lab since 2016 in oregon. sold. have some great ideas for hemp platics being implemented in regenerative agriculture and decentalized financial situtaions email me at …

Hey Ty,

Unfortunately, Exchanging contact information in the comments is not permitted under our terms and conditions. Do you maybe have a common interest on a social media application? Maybe the Sensi Seeds Instagram account is of interest to you both?

In the meantime, thanks for your comments and I hope you continue to enjoy the blog.

With best wishes,

Mark

John. I’m interested in speaking with you about this. Can you email me at Transmedia360@gmail please?

Hey Nina,

Unfortunately, Exchanging contact information in the comments is not permitted under our terms and conditions. Do you maybe have a common interest on a social media application? Maybe the Sensi Seeds Instagram account is of

interest to you both?

In the meantime, thanks for your comments and I hope you continue to enjoy the blog.

With best wishes,

Mark

I am looking for someone that can mold this compond into the shapes needed for everyday life to knock out the plastic problem in the world. I can go green and be the best representive to sell my inventory, starting with me. I will buy a contracted of 5 yrs. To start because I know it will be made out of the best product by extraction and molded into the most popular object in the world

handwritten books were made,

Good afternoon,

Thanks for your comment,

Great point, both the Magna Carta and the King James Bible were written on Hemp paper, as was the first draft of the American Declaration of Independence!

I definitely think this article on Hemp Fabrics 101 & How Hemp Textiles Are Made will be of interest to you!

Thanks again for your comment, and I hope you continue to enjoy the blog!

Have a great day!

Mark

Great article! I’m wondering if hemp plastic can be used to manufacture drinking straws since they will be banned in the EU by July 2021. Do you have any experience with that?

Hey Robert,

Thanks for your question and support.

I’m pleased you found the article interesting.

Hemp drinking straws are currently being produced and sold in North America. Being completely plant-based, they are fully biodegradable and would make a great alternative!

This article on Hemp Fabrics 101 & How Hemp Textiles Are Made may be of interest to you.

Thanks again, and I hope you continue to enjoy the blog.

With best wishes,

Mark

Where can I buy machines to produce hemp plastic or process hemp more efficiently? Something similar to Hemp Continuous Countercurrent Reactor.

Hey Askhet,

Thanks for your question. Industrial hemp is not our area of expertise, so for this kind of enquiry we recommend that you contact the Hemp Industries Association.

I hope you continue to enjoy the blog,

With best wishes,

Mark

If the hemp bottles disintegrate so quickly, how would someone buy pop or juice in one and not lose the liquid?

Good morning Connie,

Thanks for the question, and support from the United Kingdom!

For a bio-based plastic to be labeled as compostable, it must degrade at least 90 percent by weight within six months at an industrial composting facility. The environment in these facilities includes the proper levels of heat, humidity, and composition of the compost to accelerate degradation and break the chemical bonds in the material. When stored at room temperature, bioplastics are relatively stable.

This article on Hemp Fabrics 101 & How Hemp Textiles Are Made may also be of interest to you.

I hope you continue to enjoy the blog.

With best wishes,

Mark

Europe, and in Ancient Russia

works of art.

Middle Ages as in Western

I am interested in hempcrete to build homes. The northwest was devastated with fires this year. Is there a company on the west coast that builds hemp blocks or is everyone using the traditional mix and place in forms

Hi Bill,

Thanks for your comment. I suggest you get in touch with the International Hemp Association to see if they can answer your questions about hempcrete blocks? In the meantime, I hope you continue to enjoy the blog.

With best wishes,

Scarlet

Hey Bill. Let’s talk.

I really wanted to find out what the process is to make plastic from hemp.

Do you extract the starch from the plant ??

How do I take the Hurd and make it into plastic??

Hi Ernest,

Thanks for your comment and questions. I recommend that you get in touch with our sister company, HempFlax, who are experts in industrial hemp and will be able to help you find the information you are looking for. I hope you continue to enjoy the blog 🙂

With best wishes,

Scarlet

Very soon this website will be famous among all blog viewers, due to it’s pleasant content

Hey Sensiseeds,

Thank you for that topic, I’m looking for some investissors here in Barcelona that will be ready to invest in a bio hemp plastic factory. The market is just blossoming here and yet (when I googled it) nobody seem to have thought abt it. I would lime to produce hemp plastic bottles at first but I need funds…as always…

Hi Eric,

You might find the website of our industrial hemp sister company HempFlax interesting. They are now producing hemp plastic pellets! I wish you good luck with your plans.

With best wishes,

Scarlet

Hi.I want to ask how exactly is hemp plastic made.How much hemp is needed to make a kilo hemp plastic?I am sorry for my bad English and thank you 🙂

Can the plastic bottle machinery be used to make hemp bottles?

Hi Rick,

Thanks for your question. I think the answer is “it depends” – on the type of machinery, the exact type of hemp plastic (due to the variation in composite materials) and whether or not the bottles are intended for single or repeated use. Sorry I can’t give you a more specific answer! Our sister company HempFlax is currently working on plastic injection moulding techniques using hemp plastic pellets, you can contact them here. The Australian company Zeoform, who are linked to in the article, might also have more information for you depending on whether they are manufacturing bottles.

With best wishes,

Scarlet

I have a question does bio-polyethylene terephthalate (PET) contain any hemp or another plant from the cannabis family?

Hi Marco,

Not as far as I can discover. As far as I understand it, bio-PET could be made with ethanol produced from hemp biomass, but I don’t think this has been tried yet. If any of our readers have more information, please let us know!

With best wishes,

Scarlet

Stolen for czech readers! http://vasevec.parlamentnilisty.cz/blogy/biodegradovatelne-plasty-z-konopi Thank you very much!

Anyone who knows about a company that makes small boxes and paper bags made out of hemp? A lot of great information on this site, thank you.

Hi Ben,

Thank you for your positive feedback! I’m glad you are enjoying the blog. Regarding your question, I don’t know of one off the top of my head, but you could try contacting the Hemp Industries Association and see if they have any leads for you. Good luck!

With best wishes,

Scarlet

Very informative. Thank you.

Hi to all, for the reason that I am in fact keen of reading this webpage’s post

to be updated regularly. It includes nice stuff.

Pure sativa was originally an industrial hemp. As far as I know hill tribes and slaves have cultivated them into the sativa’s we know today I assume crossing with indica at some point.

Is it possible to cross a hemp seed with a different seed?

Hi Joseph,

To my knowledge, that is not possible, although there are urban legends that there have been some attempts to graft cannabis onto hops, and a hoax video on youtube about crossing cannabis with tomatoes.

With best wishes,

Scarlet

I would like to know the importance of the treatment with steam Explosion in terms of realistic aggressivity to the Lignin and what’s the best process in order to pick out it from Hemp in economical ratio

Ermanno from Italy

Hi Ermanno,

Good question! I have passed it on to HempFlax, our industrial hemp sister company, and included you in the email in case you do not see this reply. Hopefully they can give you the information that you are looking for.

With best wishes,

Scarlet

Can I also get the answer for this question?

Hi Tejasvi,

If you contact our sister company HempFlax here, they should be able to help you with any questions about industrial hemp. In the meantime, I hope you continue to enjoy the blog!

With best wishes,

Scarlet

I am interested to know what kind of estrogenic activity is found in hemp plastic as I have found several sites that have posting of scientists testing various kinds of plastics, including soy, and found all of them to exhibit EA due to the physical properties of certain monomers, yet none mention a single type that is completely EA free, and none of them mention hemp at all.

Are there any US manufacturers making hemp based, biodegradable, compostable plastic bags, and if not, are there any in the market accessible by a US small business?

Hi Carolyn,

Thanks for your comment. That’s a good question, for which I don’t have an answer, I’m afraid! If you are in the US, I suggest contacting your local branch of NORML (just google NORML followed by your area name) as they may be able to help you.

With best wishes,

Scarlet

Appreciate this post. Will try it out.49197

Do you have any video of that? I’d care to find out more details.p10993

Thanks for compiling this informative article. Another avenue for third-Party value added products chain as West Virginia moves forward with Hemp Agriculture. #WVHemp

Hi guys, interesting article as always… but how come there are no share (on social media) buttons/links?

sharing is caring 😉

Hi Cannaworld,

Thank you, glad you enjoyed it 🙂 There should be ‘share on twitter’ and ‘share on facebook’ buttons to the right of the title, at the top of the column of related posts. If you still don’t see them, please could you let me know what browser you are using and I’ll try to fix it? Thank you!

With best wishes,

Scarlet

Hi, I represent a new Hemp based TV show that will air everyday on US Television.

The program will have famous actors and celebrities on as guests .

Presently we are seeking companies interested in having their products marketed on our program.

The program plans on marketing many products free of charge.

We will show case any and all hemp based and related products, paraphernalia, clothes, shoes, foods, oils etc. etc.

Contact me asap if interested

David j.Garner

Mobile # +86~ 177~8007~4750

WeChat DAVIDJGARNER777

Hi David,

Thank you for your comment and your interest. I have passed your details and request on to HempFlax, our sister company which specializes in industrial hemp (hempflax.com)

With best wishes,

Scarlet

Hi everyone! Where I could buy hemp water bottles?

Best regards!

Hi Milan!

Thank you for your comment. I’m afraid Sensi Seeds do not yet sell hemp plastic water bottles. Our sister company HempStory sells glass bottles with hemp covers to keep the water cool, but that’s the closest we have right now. You can contact them via Facebook if you are interested in finding out more about this product. Sorry I can’t help you further,

With best wishes,

Scarlet

Sensi Seeds knocked it out of the park with this post! So much information in one place! I’d like to introduce everyone to another source(s) to needed problems. Cover Crops (like Sunn Hemp) can provide the needed fertilizers naturally and can be grown in the offseason. There is also another not talked about solution to grow a similar plant to Hemp called Kenaf. Kenaf requires less water to grow than Hemp and from my research does 80% of what Hemp plant does.

I’m also opening the door to anyone to collaborate on a future project the team and I are working on in Kenya Africa. Kenya just declared plastic bags will not be allowed in Kenya in the near future. My Kenya teammates what to use our future hemp and kenaf plants as a possible source to meet the eco-friendly demands of this industry.

DuckDuckGo suggested this page in a web search for Hemp Plastic. #HempOn Amigos!

Hi Scott,

I think this is awesome! What stage are you on? I’m super interested in how I can get involved?

Hey Scott,

I’m interested in learning more about your project in Kenya, please get in touch with me!

Thanks

How do these plastics hold up with insects? specifically bees? There are new beehive designs that use plastic as combs, but studies have been linking this as damaging to the hives, are these plastics inhert, what chemical structures make up these plastics?

Hemp can purify contaminated water for drinking and enhance the soil it’s grown in also you can ROTATE Crops and take up less water compared many other crops also no herbicides , pesticides are used or needed and give there yields including food much faster. Hemp can save California. Fertilizers are very optional with hemp.

Well Steve even being a cannabis activist, I will say that you make a good point. However, drip irrigation is a start to this solution and other less clean water sources can be used if a filter is set up in your irrigation system. Or a holding tank used to sanitize the water and then pass it through said filter. Also look up the IntelliFarms Field Data Manager. It knows exactly when you need to irrigate and before long it will automate your pivots to release just the right amount of water. Over irrigating is a big problem due to the soil only being able to take so much water in at a time while the rest simply evaporates off the top. This is where integrating technology into agriculture more will become necessary.

Cannabis hemp is way overdue and should have never been prohibited.

Your right the gas paper and cotton group and others had to stop it. In ww2 the farmers grow hemp.

With the global water shortage, is it really a viable option to replace standard practices with huge crops of super thirsty water sponges? I do agree that hemp is an amizing plant with multitudes of benifets, but how would relying solely on it for plastic production affect the amount of clean drinking water? Also hemp as a crop would reduce land used for food crops, and increased fertilizer run off into streams that ultimately end up in lakes would feed the algae blooms that further reduce drinkable water supplies. I only ask/state this because California is stating that marijuana grow ops are a major contribution to its current drought.

There is pretty much nothing you can do to destroy water. And you can always use natural fertilizers

ALL water on Earth is polluted, poisoned.

John Hutchenson purified Perdido Bay Lillian Alabama The Gulf of Mexico.

Used his 528hz machine to purify The Gulf of Mexico on a matter of Hours.

FORD made his 41 Ford out of HEMP.

Homes are now being built in HEMP

HEMP was US OF A’s main source of income in the 1700s 1800s.

Till wall street US steel, Hearst of Mountains of Trees, And DUPONT with it’s chemical Textiles, rayon, cotton etc.

Hemp is 10 times lighter and 15 times stronger than steel

Hemp can make in 4 months what trees produce in 20 years

Hemp makes better rayon, nylon than Dupont does.

SO they all had congress make HEMP Illegal

Hemp IS a food crop! OMG Steve H.. Stop commenting and start learning more about hemp. Hemp is the most nutritive wholefood there is. Best alternative to animal protein and still the best alternative to petrochemical industry. Inform yourself before commenting. Field of HEMP gives 4 times more cellulose than the same field of grown wood. And its an annual plant so it actually gives much more. Btw, water is not the problem for hemp if you are not trying to grow it in the desert. Ask someone in monsoon region if they have a problem with droughts 😉

I ordered some hemp protein once. It was horrible. Back to Soy and pea.

Hemp should be grown in the dryer areas of our planet , being such a hardy plant , you may not get the best yield in the first crops but eventually by having the plants there could create a ecosystem that would help itself.

Rain only falls where there is life . At the moment we as humans are holding alot of the water in our bodies for 50 – 100 years. The bigger the population the less water to use. We need to spread out instead of couping up in cities.

Look how much water a cow holds , and how much land it uses and destroys just for us to eat it . Do we need to eat beef ?

We need to plant as many trees as possible ,grow as much hemp as possible and try to restore our home to its former sustainable self . We need to can space exploration and explore this planet more.

I am 40 years have known this since i was 10, and my views fell on deaf ears until the last ten years . The only way to make change is through numbers and majority and perserverence .

I am a Big Hemp Fan. That said there are several Ancient Grains that contain all essential protein amino acids found in meat. Quinoa Teff Amaranth are 3 there a more.

Davor, be nice. Steve IS educating himself by posting. We need to support one another’s learning, not say “shut up unless you already know everything.” The way to spread knowledge is to keep an open dialogue. This is a highly complicated matter, and Steve is making points that we should discuss. Also….it’s more productive and respectful to simply be polite. Please keep sharing what you know, Devor, but please do not squash the concerns of others as they gain their education. We need to build, up, not tear down.

yes you are right Davor we grew hemp here in south Asia we don’t have such problems that Steve is mentioning .

Hemp is not used as bio-plastic only it have vast field of benefits i.e from paper industry to clothing. Personally i think its a revolutionary natural source.

Story about marijuana being the major contributor to California’s water shortage is a LIE! Look it up! Animal farms use most of fresh water. Google it!

And almonds…

you dont really need to water hemp crop like medicine crop

Also, Hemp can be planted as a rotation crop, to help heal soil thats damaged from monoculture etc. Its an excellent way to draw deep nutrients and fix nitrogen in the upper layers of topsoil etc. Also there are technologies, (I am working with a few) that naturally increase water retention in soil by 60% or more and nutrient retention by 80% or more. These innovation will make the industry completely sustainable, so that its benefits won’t outweigh the minor downfalls.

Also, think of all the applications for a Mars settlement. Hemp could provide oxygen, fuel, plastic, building materials, food, and medicine. All for the cost and weight of a bag o’ seeds and some soil treatment.

Keep in mind, in farming, as in life, there are no solutions…only trade-offs…

Chad

The water and fertilizer is not a problem when you replace soil with hydroponics and use fish’s poop as fertilizer then the hemp “cleans” the water so the fish would receive the fresh water afterwards… the water consumption would reduce.

Do you mean Aquaponics? Hydroponics does not involve fish at all!

To meet the levels of cellulose needed for plastic production, Aquaponic or Hydroponic production is not viable at all.

Fiber specific hemp cultivars are planted at about 50kg per Ha, and anyone that knows how small a hemp seed actually is will know 50kg is more than 50,000 seeds.This means you would need an aquaponics facility that can house 50,000 plants on one Ha of land, while reducing the production cost bellow the market value which isn’t possible at this scale.

@Steve H. Steve, the global cotton industry uses between 10 to 25 thousand liters of water to produce 1kg of cotton. India as the worlds largest cotton producing nation uses in excess of 25,000 liters per KG while 100,000,000 people live on less than a liter of clean water per day. If the Indian cotton industry diverted half of its water consumption to human consumption 600,000,000 people would have more than 100 liters of clean water a day.

Considering that Hemp uses half the water consumption of cotton, the above scenario is very viable if cotton was replaced with Hemp in India alone.

The water consumption consumed in global cotton industry is staggering, in the first 10 weeks of 2018, more than 52 billion tonnes of water has been consumed in cotton industry alone. Thats 52 trillion liters every 10 weeks.

Beyond the staggering water consumption and considering that cotton uses 20% of the worlds combined pesticide use, and more than 50% of the total pesticides used in India are for cotton production, global ground water contamination through excessive pesticides, causing even larger water shortages through pesticide saturation.

Enlighten yourself, for everyones sake please, enlighten yourself!

I am going to say the same thing I did to Davon: don’t degrade others who are being polite and trying to learn more. Steve simply expressed a concern. There’s no need to scold or belittle anyone. We need to encourage questions, concerns, and dialogues. A person does NOT need to be an expert and be able to write 5 paragraphs of hemp facts to join the conversation. Rather than sneer at someone for having less knowledge than you, know that this is a chance for you to have a solid dialogue and help someone come to a better understanding.

Elliot how can I get in touch.

Would like to chat about Hemp in India.

Rajiv Malkani

Wyoming is in the process of passing our laws right now, and water is a commodity here. But, like my property, I have a high water table, cannabis doesnt like flooding, but, if plowed property, I can use that high water table… luckily my well produces good water, and unlike most in my area, I have 750 ft well. So, technically, I can take advantage of the high water table to grow crops. And like california, our beef farms take the most water, especially for growing hay crop in order to feed those cattle, and not to mention how much water they need directly to stay hydrated in the summer time. It will take less water for me to grow cannabis compared to raising cattle. I can even use my well, even though I have an option to contact the local irrigation company and use the water from the irrigation ditch. ( I dont have to ). And still have a good well. Of course thats only growing one acre of cannabis. Now, If I used my neighbors property, 40 acres, I could still only use my well to irrigate the crop, and still have plenty of drinking water… What it really boils down to is the ground your working with, drainage, your water table and such. But, California wants to ban drinking straws because its taking up so much in dumps… well, why not cannabis straws,,, biodegradable….. Makes sense to me to go hemp over anything else, no matter what state you live in…

Once you look into the water usage of hemp, it’s not much when compared to what it will replace. Also, an acre of hemp replaces 4 acres of trees….except the help takes 4 months to grow and the trees take decades. An acre of hemp can replace 80 acres of trees over a 20 year period. Additionally, tree pulp has to be bleached to be usable. That bleach byproduct is dumped into waterways. Hemp uses hydrogen peroxide to whiten the pulp, which has no damage to waterways.

Currently, federal farm subsidies include paying farmers NOT TO GROW. There are millions of acres sitting idle to keep up prices for farmers, This land would be more than enough to produce bio-fuel to produce the endless items that can be made from HEMP. Our water shortage has more to do with raising crops (such as rice) that are not native to California. Taxing golf courses would save millions of gallons to make us the forerunner in Hemp products.

Steve, Hemp actually will not be a major polluter like many say it will be, because hemp actually gets rid of pollution and if it needs any pesticide treatments than can and should be done with natural stuff.

I am way beyond extremely ticked off that our world is in such an extremely over polluted state by pesticide companies like Monsanto, Cargill, Synegnta, Bayer of America, Chem China and ALL other pesticide companies worldwide.

Even worse is ALL nations worldwide that have pesticide companies have a government who that completely and even fully allows those pesticide companies do whatever they want to even of it is kill the citizens in their country and countries worldwide…..

So because Hemp takes kind of power away from a lot of pesticides companies and government, that is the true reason Hemp has been illegal in the USA for so long, because the USA government can not regulate it so easily it seems…..

Hell to be honest anything that the USA government can not control themselves, they make it illegal because they don’t want a freaking thing to do with it

They aren’t really that thirsty of a plant .. and my future grand kids might still have a planet. BTW 10,000 acres of hemp takes up as much water in one year that a golf course uses in a month.

Fantastic write up! Great work and information Seshata.

Goed geplaatst Martijn!

Dat Hennep het versus moderne middelen, als plastic e.d. moge winnen!

‘Red de aarde, gebruik hennep!’

(bron: Hennep.nl)